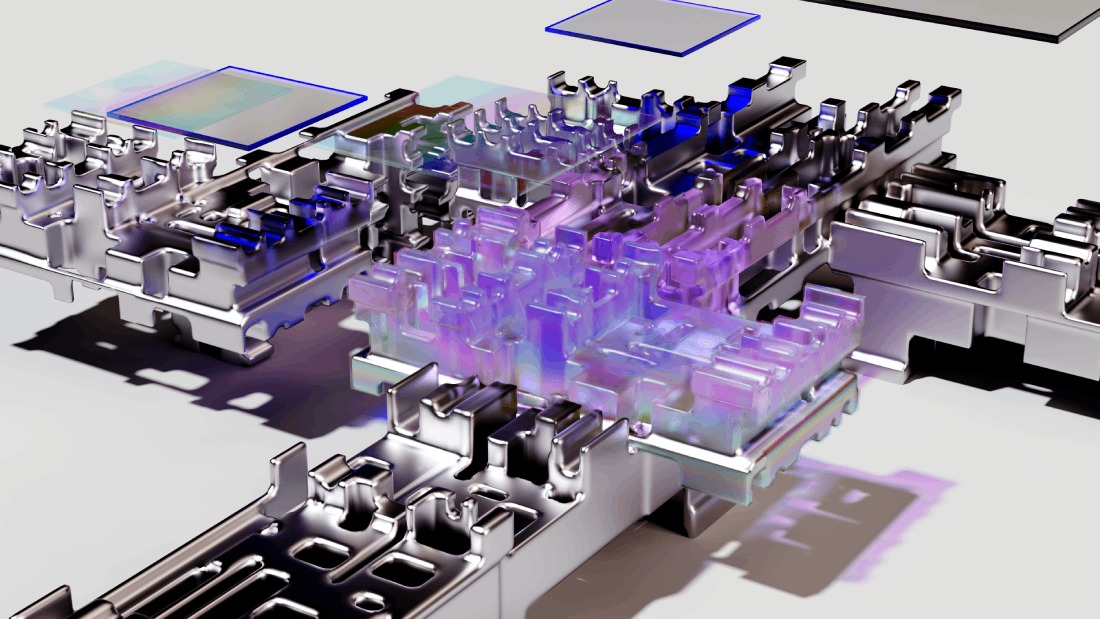

In the fast-paced world of manufacturing, staying ahead of the competition requires innovative approaches and cutting-edge technologies. One such technology that is revolutionizing the industry is digital twins.

In brief:

- Digital twins can offer manufacturers insights, enhanced efficiency and decision-making capabilities.

- Challenges include the complexity and cost of creating and maintaining accurate digital replicas.

- Digital twins can identify and rectify errors in advance, ensuring smooth execution of manufacturing plans.

These virtual replicas of physical products, machines, or systems offer numerous benefits, including improved product design, optimized production processes, and predictive maintenance. We found out what lessons we can learn from them during GDS Group’s recent Manufacturing North America virtual summit.

During the event we heard from three executives in the industry, discussing the concept of digital twins and their role in enhancing operational efficiencies and productivity in the manufacturing sector. Here’s what they had to say…

Understanding the value of Digital Twins

Digital twins provide manufacturers with a deeper understanding of their processes, allowing them to identify gaps and inefficiencies in real-time. They provide real-time visibility into machine performance, enabling operators to make immediate adjustments and improve efficiency on the shop floor.

“I think it’s a very powerful way to extract additional value even as you’re making products and are planning production.”

Sudhi Bangalore, former CTO at Stanley Black & Decker

Sudhi Bangalore at Stanley Black & Decker emphasized that digital twins empower manufacturers to extract additional value by identifying and addressing waste in processes. He explains that by bridging the gap between physical assets and processes, digital twins enable manufacturers to make informed decisions, optimize production, and achieve cost savings.

The executive says, “With digital twins, you have now the ability to identify these wastes in real-time, and you’re able to resolve them with action. You can close those gaps and therefore increase budgets, reduce scrap output, and be more productive.”

Considering Digital Twins to overcome challenges

The panel discussion highlighted several ways in which digital twins can help address common manufacturing challenges. Resolving supply chain gaps was one area where digital twins were deemed valuable.

“I think the key thing about digital twins is the ability to really understand processes in in any setting, especially on a factory floor,” shares Sudhi.

By simulating and analyzing the entire manufacturing process digitally, manufacturers can ensure smooth integration of new products into existing assembly lines and eliminate potential issues before implementation. This approach minimizes risks and ensures that manufacturing operations run seamlessly.

Baxter executive Brett Knittle shared his personal experience to illustrate the importance of digital twins in preventing costly mistakes. He recalled a situation where the length of a conveyor was measured incorrectly, resulting in significant delays and rework. With digital twins, such errors can be identified and rectified in advance, ensuring smooth execution of manufacturing plans and reducing the likelihood of mistakes.

“It’s a great opportunity to never make a mistake, which is a good goal. You’ve got to make mistakes, but you’ll make fewer with digital twins.”

Brett Knittle, Global Adv Mfg Eng & Additive Mfg Community of Practice Leader at Baxter

Larry Saidman Chief Technologist R&D at Nordson agreed, emphasizing the value of digital twins in enhancing communication and collaboration among teams. With digital work instructions based on virtual simulations, teams can execute their tasks more efficiently and accurately. This results in synchronized operations, improved productivity, and as a result – increased revenue.

“A lot of what drives the cost is the need for accuracy,” Larry shares.

Due Diligence with Digital Twins

While digital twins offer numerous advantages in manufacturing, it is important to consider the potential disadvantages and negatives associated with their implementation. One of the main challenges lies in the complexity and cost of creating and maintaining accurate digital replicas.

Building a comprehensive digital twin requires significant investment in sensors, data collection infrastructure, and integration with existing systems. Additionally, ensuring the accuracy and reliability of the data fed into the digital twin can be a daunting task, as any discrepancies or errors can lead to flawed insights and decisions.

“It takes a lot to maintain these twins.”

Sudhi Bangalore, former CTO at Stanley Black & Decker

An audience member from Medtronic says, “you may have all the technologies you need, but the cost of setting up that first train and the maintenance is really one of the challenges.” Sudhi Bangalore at Stanley Black & Decker shared his thoughts on this. “Identifying how you can make more yield is very important. So, you focus your digital training on getting more yield. This sort of cost benefit analysis has to be done… I think that’s a good way to prioritize whether it’s worth using a digital twin in or not.”

The complexity of digital twins can pose challenges for employees who need to adapt to new technologies and acquire the necessary skills to effectively use and interpret the data provided by digital twins.

Organizations must invest in training programs to upskill their workforce and ensure they can fully leverage the potential of digital twins without encountering skill gaps or resistance to change. Brett Knittle at Baxter says, “the opportunity to utilize VR to set up training videos on a line that doesn’t even exist and may not exist for two years; that’s priceless. But it’s going to be very costly.”

Embracing Digital Digital Twins

Digital twins have emerged as a game-changing technology in the manufacturing industry, offering manufacturers unparalleled insights, enhanced efficiency, and improved decision-making capabilities. The future with digital twins is an exciting and transformative one.

As this technology continues to evolve, it is essential for manufacturers to invest in the necessary infrastructure, talent, and collaborative partnerships to fully harness the potential of digital twins and shape the future of the industry.

Our recent Manufacturing North America virtual summit had ended with an impressive average content attendance of 96% and meeting completion rate of 127%.

Partnering with GDS Group can help you get in front of the right people at the right time.

Don’t miss out on the opportunity to attend one of our unforgettable event experiences that promise to leave you feeling inspired and empowered.

Check our calendar now and join us. We can’t wait to see you there!