In the era of Industry 4.0, the role of artificial intelligence (AI) in manufacturing has become a topic of hope and hype. But what does AI truly mean for the manufacturing sector? At the recent GDS Group Manufacturing North America summit, Arun Kumar Bhaskara-Baba, Chief Information Officer at Honeywell Aerospace, shed light on this question.

He presented his five key points for harnessing the power of AI:

- Purpose

- Pilot

- Pivot

- Promote

- People

In this article we look at the significance of each point in driving the adoption of AI in Industry 4.0.

In brief:

- Data management, cost and complexity, workforce education, ethical considerations, integration, and interoperability are additional challenges to be considered

- A mindset shift has been highlighted as “extremely critical” for successful AI implementation

- The importance of aligning AI with business goals and fostering collaboration between humans and AI systems is key

Purpose: Aligning AI with business goals.

The purpose serves as the foundation for AI implementation in manufacturing. Arun emphasized the need to identify the real business challenges and determine where AI can have the most significant impact.

“It all depends on what the purpose is that you are driving and how fast and nimble your organization can shift.”

Arun Kumar Bhaskara-Baba, Chief Information Officer at Honeywell Aerospace

He explained that understanding the purpose enables manufacturers to prioritize their efforts and focus on areas that provide the highest value, such as improving labor productivity, addressing labor shortages, and meeting sustainability expectations.

Pilot: Testing the waters.

To validate the potential of AI, organizations must conduct pilots or proof-of-concept projects. Arun stressed the importance of piloting initiatives in areas where data is readily available, and integration is feasible.

One example he shared was the deployment of AI in Honeywell Aerospace’s Indian operations, specifically in visual inspection during the repair and overhaul process. By choosing a use case with sufficient data, integration capabilities, and significant business challenges, manufacturers can demonstrate the value of AI and gain confidence in its potential.

Pivot: Adaptability and learning from failure.

In the fast-paced world of AI implementation, the ability to pivot quickly is crucial. Arun emphasized that organizations should not get stuck in pilot purgatory but rather pivot when necessary.

“Somebody has to call timeout and say pivot.”

Arun Kumar Bhaskara-Baba, Chief Information Officer at Honeywell Aerospace

It is essential to recognize when a pilot project is not yielding the expected results and have a backlog of alternative use cases ready for exploration. By being adaptable and willing to make strategic shifts, manufacturers can optimize their AI initiatives and ensure long-term success.

Promote: Transforming mindset and driving adoption.

Promoting AI within an organization involves transforming mindsets and overcoming resistance to change. Arun highlighted the importance of addressing the fear and skepticism that may exist among employees, particularly those who interact directly with manufacturing processes.

The CIO says, “You want to make sure that you carefully promote the value you are seeing, and what the lessons learned are so that you can actually continue to improve and get to the next pilot.”

He emphasized the need to educate and engage the workforce, showcasing how AI can enhance their roles and improve operational efficiency. By promoting a culture of embracing AI and its potential, organizations can drive widespread adoption and maximize its benefits.

People: The Human-AI collaboration.

While AI brings immense potential, Arun emphasized that people remain central to successful AI implementation. He highlighted the need for a leadership mindset that recognizes the value of AI and guides its integration into operations.

Empowering employees with the necessary skills and knowledge to work alongside AI is vital. Workforce education becomes crucial in ensuring a smooth collaboration between humans and AI systems, leveraging the strengths of both to drive manufacturing excellence.

Challenges in AI accelerating industry in manufacturing.

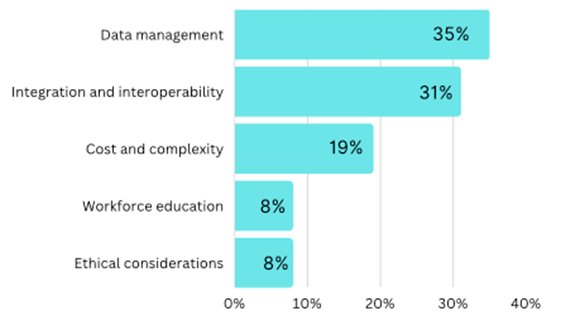

As well as Arun’s five points above, several other challenges in adopting AI for Industry 4.0 in manufacturing were discussed. The summit audience took part in a digital poll, to explore which challenges were most significant to them. Here are the results…

Data management:

One of the most significant challenges in leveraging AI for Industry 4.0 is the collection and analysis of large volumes of data generated in manufacturing processes. Effectively feeding AI algorithms with quality data is essential for accurate insights and predictions.

Cost and complexity:

Implementing AI technology in manufacturing can be costly and complex. This aspect often poses a barrier, making it challenging for smaller manufacturers to adopt and benefit from AI solutions.

Workforce education:

To effectively utilize AI and work alongside it, employees require adequate training and education. Ensuring that the workforce has the necessary skills and knowledge to leverage AI’s capabilities is crucial for successful implementation.

Ethical considerations:

The ethical use of AI is a paramount concern. Manufacturers must ensure that AI is implemented and utilized in an ethical and responsible manner, considering privacy, security, and the potential biases that AI systems may exhibit.

Integration and interoperability:

AI systems need to integrate seamlessly with existing manufacturing infrastructure and communicate with other machines, sensors, and platforms. Establishing interoperability is vital to create a cohesive and efficient AI-powered manufacturing ecosystem.

The mindset shift is “extremely critical”:

Although mindset was not mentioned in the poll, it’s an “extremely critical” aspect highlighted by Arun. Overcoming fear and resistance and fostering a mindset that embraces AI as a tool to drive operational efficiency is vital.

This requires asking the right questions, as Arun says, “How do you actually transform the mindset of the operators on the floor, the people who are running the operations day-to-day, and the management about what their business is?” The answers should enable leaders to see the benefits and value that AI can bring to their work.

Arun says, “The social economics of AI is going to have a big impact. So, unless you have that mindset of how it helps your business, how it helps your organization, and how it helps you, it’s going to be a big challenge to overcome.”

Conclusion:

The five key points of purpose, pilot, pivot, promote, and people serve as a roadmap for manufacturers integrating AI into operations. Aligning AI with business goals, conducting pilots, being adaptable, and promoting AI adoption are crucial. However, challenges like data management, cost, workforce education, ethics, and integration must be addressed. Collaboration between humans and AI is vital. By following these principles and addressing challenges, manufacturers can unleash AI’s power, improving productivity, addressing labor shortages, and driving manufacturing excellence. Embracing AI with the right mindset paves the way for a transformative future in the industry.

Looking for ways to accelerate your sales cycles, engage in industry conversations, and achieve better outcomes? Look no further than our Summits – our unique 3-day digital event experiences that bring together senior executives and solution providers.

Our recent Manufacturing North America digital summit had Arun as a speaker and ended with an impressive average content attendance of 96% and a meeting completion rate of 127% against target.

Partnering with GDS Group can help you get in front of the right people at the right time.

Don’t miss out on the opportunity to attend one of our unforgettable event experiences that promise to leave you feeling inspired and empowered.

Check our calendar now and join us. We can’t wait to see you there!